Exterior Envelope Study Improves Thermal Comfort and Realizes SavingsWhen Penn State Health selected Flad as architect for the Penn State Hershey Medical Center (PSHMC) Hospital South Addition Level 7 MICU Renovation, the scope was to provide planning, design, and documentation services for a full renovation of the top floor in the hospital's South Addition.

Upon selection, the PSHMC project manager suggested reviewing the exterior window and envelope conditions as he believed there were condensation concerns with the existing windows. After a cursory review of the existing drawings, Flad's team quickly ascertained that there were likely thermal performance issues. The wall sections and details from the facility, constructed in the late 1980s, appeared to have significant areas for thermal bridging around the perimeter.

During the schematic design phase, Flad and the MEP consultant, Leach Wallace, completed a detailed study that addressed concerns relating to the hospital's existing perimeter conditions, specifically winter condensation occurrences in the NICU. Through field work, systems analysis (both architectural and MEP), and energy modeling, the team proved high-performance window and wall upgrades would be a prudent investment. The selected thermally enhanced window system allows for correctly sized new rooftop air handling units, cutting 600 cubic feet per minute off unit sizes and providing cost savings of $150,000.

Window and Wall Woes

Exterior Envelope Study Improves Thermal Comfort and Realizes SavingsWhen Penn State Health selected Flad as architect for the Penn State Hershey Medical Center (PSHMC) Hospital South Addition Level 7 MICU Renovation, the scope was to provide planning, design, and documentation services for a full renovation of the top floor in the hospital's South Addition.

Upon selection, the PSHMC project manager suggested reviewing the exterior window and envelope conditions as he believed there were condensation concerns with the existing windows. After a cursory review of the existing drawings, Flad's team quickly ascertained that there were likely thermal performance issues. The wall sections and details from the facility, constructed in the late 1980s, appeared to have significant areas for thermal bridging around the perimeter.

During the schematic design phase, Flad and the MEP consultant, Leach Wallace, completed a detailed study that addressed concerns relating to the hospital's existing perimeter conditions, specifically winter condensation occurrences in the NICU. Through field work, systems analysis (both architectural and MEP), and energy modeling, the team proved high-performance window and wall upgrades would be a prudent investment. The selected thermally enhanced window system allows for correctly sized new rooftop air handling units, cutting 600 cubic feet per minute off unit sizes and providing cost savings of $150,000.

Study Highlights

- The existing windows did not meet the minimum performance building codes at the time of construction (i.e., ASHRAE 90.1.1989 requires a Window System U-value of 0.52. The hospital's existing windows had a U-value of 0.59, thus did not meet the code requirement).

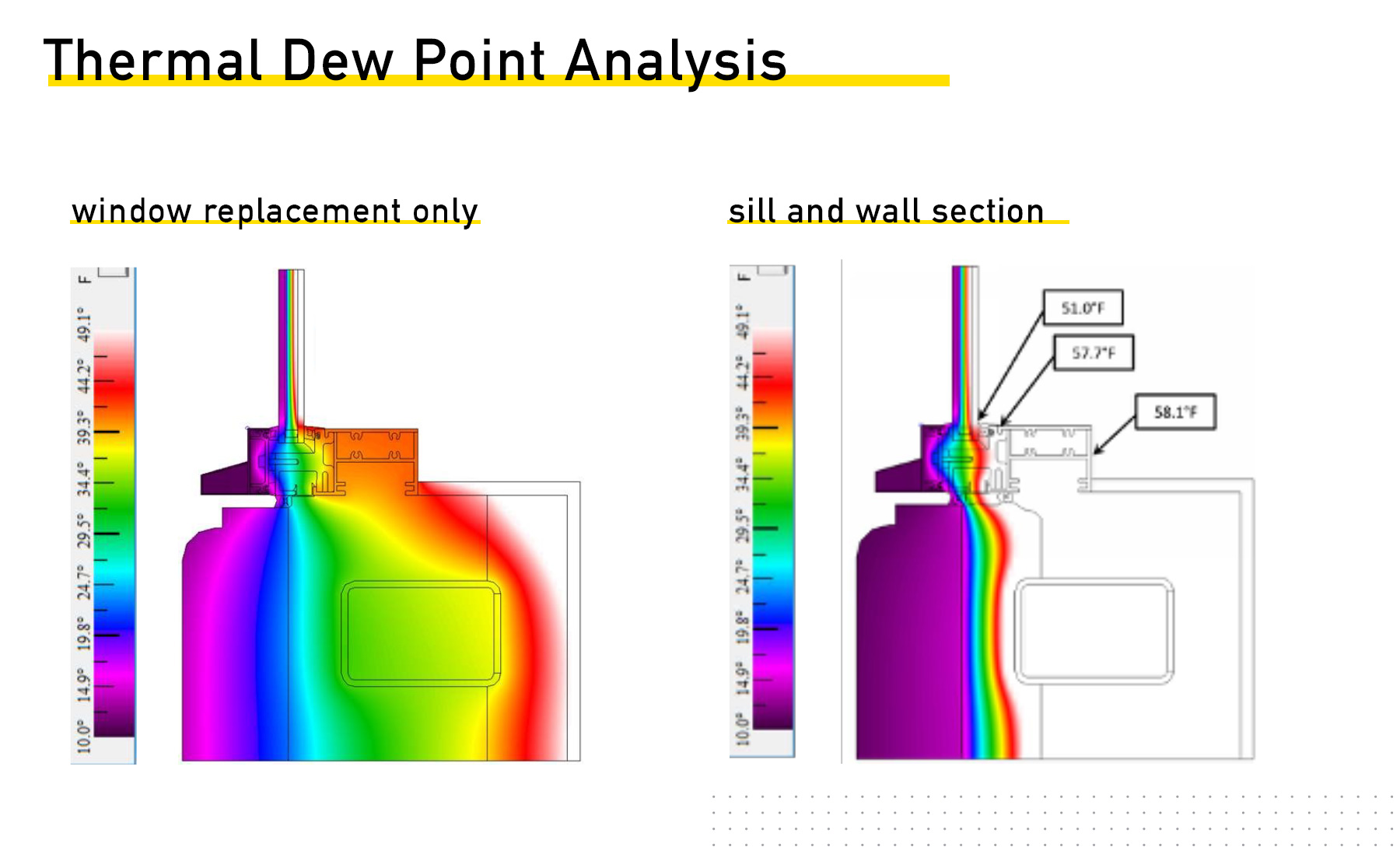

- Existing detailing and perimeter conditions created extensive thermal bridging opportunities (i.e., Flad calculations showed that under worst-case winter conditions, concrete floor slab temperatures 2’-0” into the building could be under 50 degrees Fahrenheit).

- Original perimeter heat registers had been disabled over the life of the building, further compounding perimeter issues and condensation concerns (i.e., In reviews with the clinical team, it was made known that staff often covered the window sills with towels and moved NICU bassinets away from the exterior wall during the winter months).

- Flad investigated options for window and exterior wall upgrades that were evaluated against the most stringent current code requirements to ensure compliance and maximum efficiency. (i.e., ASHRAE 90.1.2013 Exterior Wall Assembly U-value of 0.055 and IECC 2015 Window System U-value of 0.38).

Flad Recommendations / Approved Option:

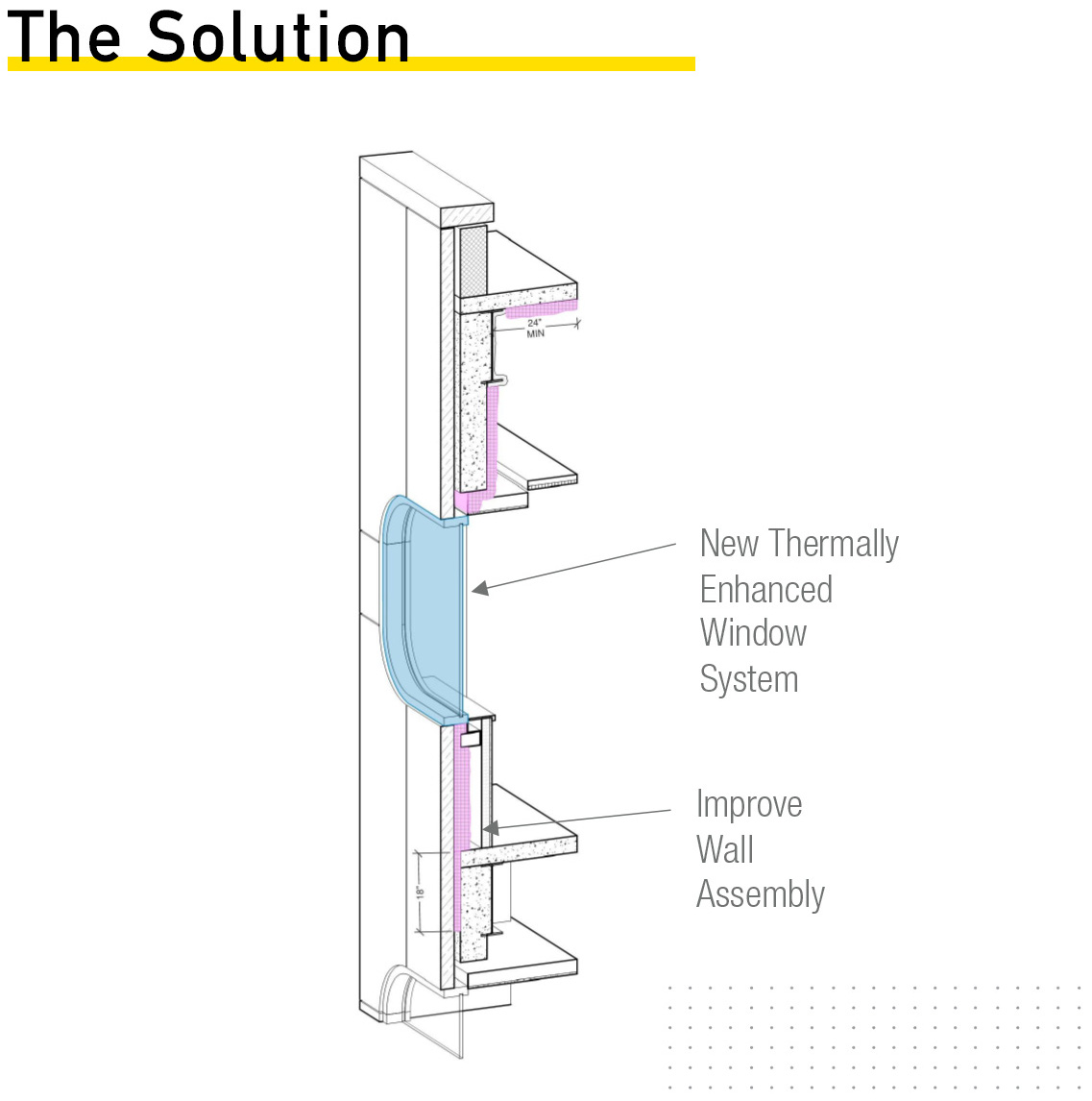

- Windows – Flad recommended utilizing a thermally enhanced window system with a fiberglass stem and pressure plate; 1" insulated glazing unit (IGU) that has a Glass System U-value of 0.279 (code min. 0.38).

- Opaque Wall Areas – Flad recommended utilizing a continuous spray foam insulation with a half-inch, spray-applied thermal barrier behind the four-inch thick limestone cladding. The insulation line extends between the downturned concrete edge beam and the perimeter cladding to interrupt the thermal bridging at the floor line.

Mechanical Performance and Benefits

- Thermographic analysis shows the window system's U-value of 0.279 not only exceeds code, but resists condensation potential within the tested design parameters (10 degrees outside, 75 degrees inside; 40% RH).

- It is important to note that the thermographic analysis does not account for any interior air supply or movement. Based on all the evaluations and the warm interior frame and glass temperatures shown under winter design conditions, it was decided that the perimeter radiant ceiling panel system could be eliminated in the final design. Per the pricing study completed by the CM, elimination of the entire radiant panel system at the perimeter resulted in cost savings of $200,000.

- When the recommended improvements were evaluated against the existing conditions to determine the effect on the sizing of the two new air handling units planned for the floor, it was determined that 6,000 cubic feet per minute could be cut off the size of these two new units. Per the pricing study by the CM, this results in a savings of $150,000 ($25/cfm).

Thermal Comfort and Yearly Energy and Cost Savings

- The primary objective of this study, and of the approved solution, will greatly enhance the comfort of all the building users, including patients, visitors, and staff.

- The team performed Life Cycle Cost Assessments (LCCA) of the recommended solution. Over a period of 25 years, the LCCA energy savings were calculated to be in excess of $475,000.